Understanding 3D Automated Inspection System

An automated inspection system is any system that automatically checks the product against pre-programed criteria. It may use optical sensors, ultrasonic sensors, or X-rays. AOI are used in many industries. They may verify that industrial pipes have the necessary thickness and are properly welded. Or they may verify that components are properly placed and soldered on a small circuit board.

The automated system may rely on simple verification criteria such as making sure the components fit within geographic boundaries. Or it may use an advanced algorithm to verify measurements and flag defects. These algorithms rely on geographic pattern matching to determine whether or not the board in front of it passes the quality check. Here are some items that you need to know about 3D automated optical inspection.

What is an optical inspection system?

An optical inspection system can best be understood as a replacement to the human QC operator. The optical inspection system is looking at the raw part or assembled item and verifying it falls within acceptable parameters. Optical inspection systems can be used at any point in the manufacturing process. Ideally, it is used both during production and in post-product inspection.

Optical character recognition may or may not be part of an optical inspection system. If it is, then the system can record the serial numbers of the defective items or identify defective printed text on the PCB.

What is an automated optical inspection system?

In simplest terms, it provides a fully automatic inspection using optical systems. The biggest benefit of this process is speed. A 3D AOI system can verify component placement before you move on to the next stage of production, and it can keep up with high volume manufacturing processes. That isn’t possible if you rely on a team of human quality control technicians. For example, using 3D AOI in conjunction with part placement systems can increase the cycle time while reducing the defect rate.

More importantly, automated 3D inspection allows you to improve the quality of your operation across the board. For example, an automated optical system can check the layout of a printed circuit board before you melt the solder. Defects in the board and the solder can be found pre reflow and post flow. However, pre-flow is always cheaper because you haven’t wasted time and energy melting the solder. And you don’t have to remove the solder to fix a broken SMA connector or reposition it. You can catch defects early on and repair them. You don’t have to worry about 2D systems missing voids in solder or overlooking missing components. And you won’t have defects escape and reach the end user, because you’re relying on statistical sampling.

How does automated optical inspection work?

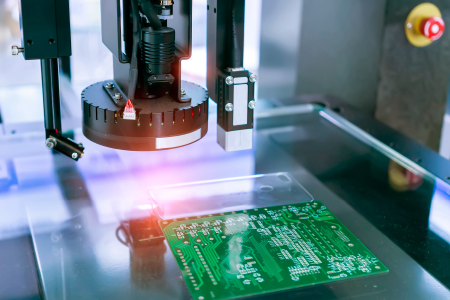

The automated optical inspection or AOI process has an automated visual inspection unit scan the device, looking for defects. Automated optical inspection can check for a variety of problems. At the most basic level, it verifies that components are present and in the right location by looking down at the board. Some systems use lasers in addition to lights and cameras that mimic a human inspector.

What is 3D AOI?

3D AOI stands for 3D automated optical inspection. 3D AOI inspects assembled printed circuit boards and other electronics in three dimensions. This is in contrast to 2D AOI or two-dimensional automated optical inspection. This typically involves a camera to verify that the items meet quality standards, whether making sure it is the right size or items are in their proper locations.

A 3D AOI system uses vertical and side cameras to see all sides of the board. This is why 3D AOI can recognize when components are skewed or flipped. More intelligent systems can recognize defects like excessive solder joints and uneven solder. These systems rely on multi-stage lighting to provide adequate light for the machine vision lens. Circular lighting is ideally, since it eliminates the possibility of shadows that could cause false calls. One point in favor of 3D AOI is that it can identify defects of 10 ppm or less. This reduces the risk of giving assembled boards a green light when there are actually small defects that should cause it to fail.

What are the benefits of 3D automated optical inspection?

We’ve already mentioned the greater overall quality level 3D inspection provides. You’ll have lower false call and escape rates, and you’ll get it at a lower price. All AOI systems have the benefit of being non-contact. This type of inspection cannot damage components. And it is the ideal solution for inspecting PCBs being made in a clean room.

3D inspection is by definition more thorough than 2D inspection. You will see more than solder voids and missing solder. You’ll see incomplete blobs of solder that won’t create the ideal circuit path. You’ll be able to verify component placement is accurate in three dimensions. This is necessary in anything more complex than a simple printed circuit board. Even layered printed circuit boards benefit from 3D automated optical inspection, such as when you verify grooves in the board and solder pads are the right height. 3D inspection systems often allow you to check solder joints and components at the same time. Then the additional level of inspection doesn’t compromise your cycle time.

Only 3D AOI will identify tombstones and lifted leads. 2D automated inspection systems won’t catch these problems. 2D systems aren’t as good at inspecting j-leads and complex geometric structures, either.

A side benefit AOI inspects is that the system collects information for later analysis. You can determine the rate at which solder balls and voids are formed on your printed circuit board PCB assemblies. You could analyze the slow drift of a component placement machine until things were out of specification. You could generate SPC charts based on 100 percent data collection from AOI. Then you can see the variations in quality as well as the productivity of various operators. Then you can address the root causes of poor quality in your manufacturing process, whether you need to provide better training for specific individuals or adjust operating parameters for the night shift.

Furthermore, you can track quality levels in real time. A quality engineer could be automatically notified by your 3D inspection system when there is a serious problem or several defective boards in a row. Problems can be addressed as soon as they occur. This reduces the odds that your team will accidentally produce 200 defective PCB boards before someone realizes there is an issue.

Does 3D AOI force me to change my manufacturing process?

You can combine 2D and 3D inspection in an existing assembly line. For example, you could add 3D inspection to the post-flow inspection while leaving 2D inspection at the pre-flow inspection stage. Depending on the equipment you select, 3D AOI equipment may be a direct replacement for your current 2D inspection system.

If you would like to learn more about automated inspection systems, don’t hesitate to reach out to the professionals at Geospace Technologies. Since 1980, we have stayed at the forefront of engineering and manufacturing innovation. Contact us or submit a form about your inquiry.