Injection Molding Services

Come see for yourself

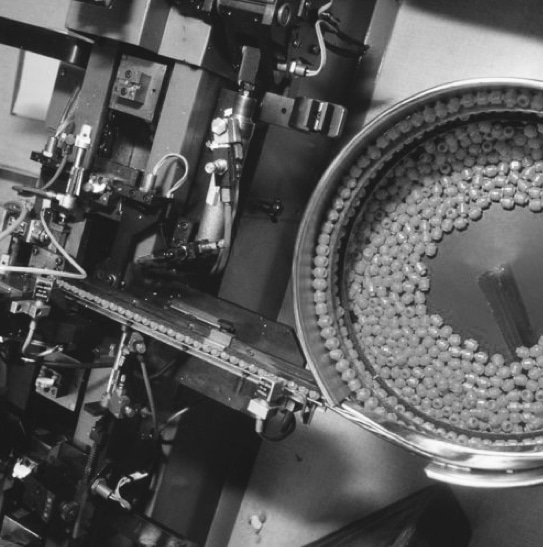

Geospace Technologies is one of the top injection molding companies in Houston. We have extremely high expectations of ourselves, so clients can be assured that we will strive to exceed their expectations as well. When it comes to our plastic injection molding services we set ourselves apart in several ways, always being mindful of the final product.

Capabilities

- Materials:

- Polyethylene

- Polypropylene

- Nylons

- Custom compounded plastics including glass, metal, and mineral filled

- In House Tooling Design & Fabrication

- Shot sizes up to 90oz

- 35+ Machines with multi-shift availability

We provide excellent quality, using only the best materials when we perform the manufacturing process of injection molding. This can be performed with several materials including polyethylene, polypropylene, nylons, and custom compounded plastics including glass, metal, and mineral-filled. In an effort to ensure a stable and repeatable process, we utilize automation whenever possible. This is all done with cost-efficiency in mind.

We work closely with our clients in all aspects of product design, tooling options, and material selections. This results in your injection mold project culminating to a result that you will find satisfactory. We know that one of the basic reasons for utilizing injection molding is to make cost-effective products that will drive your sales.

In addition, we strive to operate in a safe environment. Injection molding requires the use of a ram or screw-type plunger to force molten plastic material into a mold cavity resulting in the shape conforming to the mold. We want our clients to rest assured knowing that their products are being created by a team dedicated to not only using the correct processes but doing so safely.

By utilizing the best materials and keeping the tooling design and fabrication process in-house, we can control the quality and make sure it exceeds your expectations. Our flexible manufacturing operations can meet a wide range of OEM requirements efficiently and cost-effectively. As a global manufacturer, you’ll have access to a world-class team to get the quality and service you require.

Design and Engineering

Geospace offers in-house tooling design and engineering support to ensure quality.

Machines

Wide assortment of machines including Cincinnati, Arburg, Wabash, AutoJector, MiniJector, and Van Dorn.

Materials

Through our partnerships with the world’s leading resin manufacturers and resin compounders we can offer solutions to complex applications.

Quality

By controlling the supply chain and having in-house tooling design and fabrication we ensure a stable, repeatable process.

Dedication to Excellence

When partnering with Geospace you know quality is important. With a constant focus on exceeding customer expectations, increasing productivity, and reducing unnecessary costs, Geospace strives for excellence. It is reflected by how we conduct ourselves as individuals and as a company. To embrace excellence, we emphasize education, training and development of employees and teams. It is a continuing quest.

Dedication to the Environment

Geospace is dedicated to protecting the environment. Creating a culture where the health and safety of our employees and the protection of the environment is considered in all operating decisions, including those related to planning and acquisition. Geospace Technologies is committed to zero harm to people, property, and the environment in everything we do.